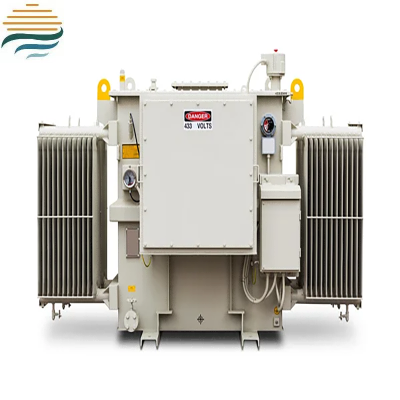

Low Viscosity Insulation Fluid for HV Transformers

In power transmission and transformation projects, transformer oil functions as a key insulating and heatdissipating medium for transformers, significantly influencing the safe operation of substations. Thus, the basic functional requirements for transformer oil include efficient insulation and heat dissipation, while high withstand voltage and low dielectric loss are critical electrical performance requirements. As highvoltage power transmission technology evolves, transformer oils must also provide high oxidation stability, thermal stability, and good resistance to gas precipitation to adapt to highvoltage conditions. Furthermore, stringent control over trace water and particulate impurities has become a priority.

Product Details:Silicone Based Dielectric Cooling Oil

In the operation of a transformer under load, “copper consumption” and “core loss” generate heat. If this heat is not removed from the coils, it will accumulate, causing the temperature within the iron core to rise. This can damage the solid insulation surrounding the coil, potentially leading to coil burnout. The use of transformer oil helps manage this heat; the oil absorbs the heat generated within the coils and then circulates to dissipate it, ensuring the equipment operates safely.

Parameter:

Sports Event | Quality Indicators | measured value | Test Methods |

Functional characteristics | |||

Pour Point/°C | -50 | -57.5 | ISO 3016 |

Kinematic viscosity (40℃)/(m㎡/s) | ≯12 | 9.52 | ISO 3104 |

Kinematic viscosity (-10°C)/(mm²/s) | ≯1800 | 1028 | ISO 3104 |

Water content/(mg/kg) | ≯30/40 | 9.0 | IEC 60814 |

Breakdown voltage/kV (untreated oil) | ≮30 | 64.5 | IEC 60156 |

Density (20°C)/(g/ml) | ≯895 | 886 | ISO 12185 |

Dielectric loss factor (90°C) | ≯0.005 | 0.0005 | IEC 60247 |

Refining/stabilizing properties | |||

exterior condition | Clear and transparent, free of sediment and suspension (of atmospheric pollution) | Clear and transparent, free of sediment and suspension (of atmospheric pollution) | visual assessment |

Acid value (mgKOH/g) | ≯0.01 | 0.0008 | IEC 62021- 1 |

Interfacial tension/(mN/m) | No general requirements | 45.3 | ISO 6295 |

Total sulfur content (mass fraction)/% | No general requirements | No general requirements | ISO 14596 |

corrosive sulfur | non-corrosive | non-corrosive | DIN 51353 |

Content of antioxidant additives (mass fraction)/percent Oil with antioxidant additives (U) | ≯0.08 | 0.065 | IEC 60666 |

2-Furfural content/(mg/kg) | ≯0.1 | 0.012 | IEC 61198 |

Operational characteristics | |||

Oxidation stability (120°C) Test time: 332h | - | - | - |

--Total acid value (in KOH)/(mg/g) | ≯1.2 | 0.04 | IEC 61125 Act C |

--Oil sludge (mass fraction)/% | ≯0.8 | 0.020 | IEC 61125 Act C |

--Dielectric loss factor (90°C) | ≯0.500 | 0.004 | IEC 60247 |

Gassing/(mm/min) | No general requirements | No general requirements | IEC 60628 |

Health Safety and Environmental Characteristics (HSE) | |||

Flash point (closed)/°C | ≮135 | 148.2 | ISO 2719 |

PCA content (mass fraction)/% | ≯3 | 0.8 | BS 2000 Part 346 |

Polychlorinated biphenyl (PCB) content/(mass fraction)(mg/kg) | undetectable | undetectable | IEC 61619 |

1. Applicable Industry

Drilling equipment: As a lubricant, transformer oil reduces friction and wear, helping to maintain equipment stability even in high-temperature settings.

Oilfield Electrical Equipment: Transformer oil is crucial in oilfield electrical equipment, providing insulation and cooling to guarantee reliability in demanding conditions.

Electric Locomotives: In the electrical systems of electric locomotives, transformer oil is used for insulation, ensuring safe electric current transmission and aiding in heat management.

Signal Systems: In railroad signaling systems, transformer oil functions as an insulating medium, ensuring the signaling system operates efficiently and safely.

2. Oil Change Inspection

Evaluating the operational condition of a transformer involves reviewing its history and maintenance logs. If there have been recurrent failures or signs of reduced performance, it may be essential to assess the quality of the oil and consider a replacement. Furthermore, it’s important to judge based on the transformer's design life and age. Should the transformer be approaching or exceeding its intended lifespan, replacing the transformer oil could be vital for ensuring ongoing safe operation.

Own Factory

The multifunctional conference room of Haikun facilitates communication and cooperation.

Employees at Working

Haikun's foreign trade employees are well - informed about industrial oil competitors. Their analysis helps us stay ahead in the market.

Canned Oil Products

Haikun Petrochemical Technology Co., Ltd. has mastered the packing for sea - freight operations. We use 200L steel containers and 20000L flexitanks for safe delivery of oils.

Transportation

Haikun Petrochemical Technology Co., Ltd. has efficient sea - freight procedures. We use reliable channels to send transformer oils to South America, Africa, and Russia.

Enterprise Culture

Firmly believing that continuous learning is the key to staying current with the times, we motivate our employees to sustain their enthusiasm for learning, actively acquire new knowledge and skills, and continuously refine their overall qualities, aiming to inject fresh impetus into the enterprise's development.

Customer Testimonials

Haikun Petrochemical's industrial lubricants have served me well. They respect customers and offer products with accurate parameters. The sales team helped me choose the right one. Trustworthy company. - Southeast Asia, Tran Van Nam