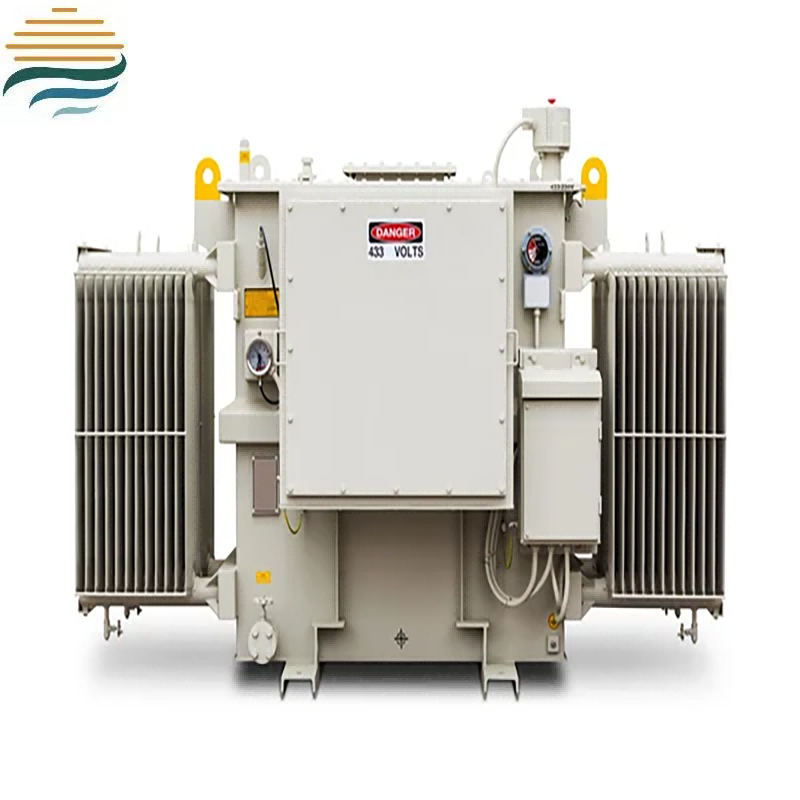

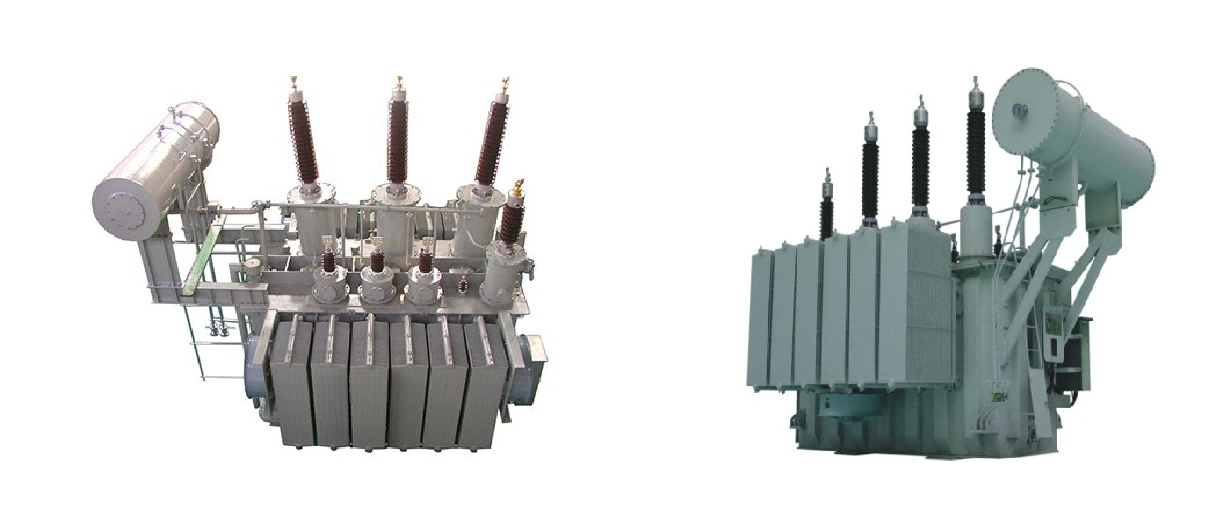

Oil-Immersed Self-Cooling Transformers

Suitable for a variety of harsh environments, oil-immersed transformers show their excellent adaptability. Whether it is the cold polar or hot desert, its sealed structure and weather-resistant materials can ensure the long-term stable operation of the transformer, providing stable power support for remote areas.

Product Details:Oil-Immersed Self-Cooling Transformers

Oil-immersed transformers play a crucial role in the construction of smart grids. An integrated intelligent monitoring and control system allows for real-time monitoring of operational status, advance warning of potential faults, and substantial support for the intelligent operation and maintenance of the power grid.

PARAMETER:

Sports Event | Quality Indicators | Test Methods | ||||||

Viscosity grade | 100 | 150 | 220 | 320 | 460 | 680 | ||

Kinematic viscosity (40°C) mm²/s) | 90-110 | 135-165 | 198-242 | 288-352 | 414-506 | 612-748 | GB/T265 | |

Viscosity index | not less than | 90 | 90 | 90 | 90 | 85 | 85 | GB/T1995 |

Open flash point,℃ | not less than | 200 | 200 | 200 | 200 | 200 | 200 | GB/T3536 |

Pour point,°C | not exceeding | -12 | -9 | -9 | -9 | -9 | -5 | GB/T3535 |

Steel sheet corrosion(100°C,)(3 hours)/grade | not greater than | 1 | GB/T5096 | |||||

Corrosion test(distilled water) | rust-free | GB/T11143 | ||||||

Foaminess (Foam propensity/foam stability) mL/mL 24°C 93.5°C Post 24°C | not greater than not greater than not greater than | 50/0 50/0 50/0 | GB/T12579 | |||||

Tim ken test(OK load) /N(Lb) | not less than | 267(60) | GB/T11144 | |||||

Anti-emulsification (82℃)Water in oil /%(mass fraction), emulsion layer /ml,total separated water/ml | not greater than | 2.0 1.0 80.0 | GB/T8022 | |||||

Four-ball test Load wear index/ N Sintering load(P value)/N | not less than not less than | 441(45) 2450(250) | GB/T3142 | |||||

CL-100 Gear Test (A/8.3/90) | not less than | 12 | >12 | >12 | >12 | >12 | >12 | SH/T0305 |

1. Selection Notes

Central to transformer evaluation are the performance indicators of efficiency, temperature increase, insulation quality, and other essential elements, all of which play a vital role in determining the transformer's operational effectiveness and reliability. To maintain cost-efficiency, the selection process must meticulously consider the costs associated with the equipment itself, transportation, installation, and other pertinent factors, ultimately identifying the transformer model that offers the greatest overall value.

2. Preparation for Installation

Customizing Transformer Selection for Space: Choose the transformer model and installation method that are compatible with the unique spatial requirements of the installation site.

Adapting to Environmental Challenges: Assess the transformer's resilience to environmental factors like temperature, humidity, and altitude to ensure it meets the installation environment's demands.

Own Factory

Employees at Working

Canned Oil Products

Transportation

Corporate Culture

Integral to our corporate fabric is the practice of lifelong learning. Confronting the challenges of our constantly evolving era, we motivate our team to consistently seek out new learning opportunities and skills, maintaining a relentless curiosity and a probing mindset. Drawing upon internal training programs, external partnerships, and a variety of means, we join forces to foster a learning-centric community, where personal progress and corporate advancement are in tune.

Customer Reviews

"In Venezuela, we've tried several suppliers for our industrial lubricant needs, but Haikun Petrochemical stands out. Their products are reliable, and their logistics are efficient, ensuring minimal downtime for our operations." — Venezuela, David Hernández