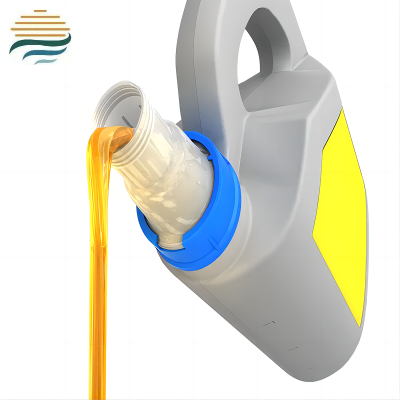

Transformer Oil T-10

Transformer oil produced by our company can still maintain good chemical stability under high temperature and oxidizing conditions, not easy to oxidize and decompose, and can maintain performance for a long time. Transformer oil also added the right amount of antioxidants, further improve the chemical stability, can effectively insulate, cooling, protect the machine, play an excellent effect.

Product Details:Transformer Oil T-10

Our transformer oil is formulated to exhibit low volatility, preserving stable oil quantities within equipment and mitigating the risk of accidents due to oil shortage. Additionally, its exceptional corrosion resistance effectively safeguards against chemical reactions and corrosion, underscoring its commitment to safety and delivering outstanding quality.

PARAMETER:

Sports Event | Quality Indicators | measured value | Test Methods |

Functional characteristics | |||

Pour Point/°C | -20 | -36.8 | ISO 3016 |

Kinematic viscosity(40℃)/(m㎡/s) | ≯12 | 9.13

| ISO 3104 |

Kinematic viscosity(-10°C)/(mm²/s) | ≯1800 | 1089 | ISO 3104 |

Water content/(mg/kg) | ≯30/40 | 6.3 | IEC 60814 |

Breakdown voltage/kV(untreated oil) | ≮30 | 62.4 | IEC 60156 |

Density(20°C)/(g/ml) | ≯895 | 886 | ISO 12185 |

Dielectric loss factor(90°C) | ≯0.005 | 0.00041 | IEC 60247 |

Refining/stabilizing properties | |||

exterior condition | Clear and transparent,free of sediment and suspension(of atmospheric pollution) | Clear and transparent,free of sediment and suspension(of atmospheric pollution) | visual assessment |

Acid value(mgKOH/g) | ≯0.01 | 0.0008 | IEC 62021- 1 |

Interfacial tension/(mN/m) | No general requirements | 46 | ISO 6295 |

Total sulfur content(mass fraction)/% | No general requirements | No general requirements | ISO 14596 |

corrosive sulfur | non-corrosive | non-corrosive | DIN 51353 |

Content of antioxidant additives(mass fraction)/percent Oil with antioxidant additives(U) | ≯0.08 | 0.059 | IEC 60666 |

2-Furfural content/(mg/kg) | ≯0.1 | 0.012 | IEC 61198 |

Operational characteristics | |||

Oxidation stability(120°C) Test time:332h | - | - | - |

--Total acid value(in KOH)/(mg/g) | ≯1.2 | 0.04 | IEC 61125 Act C |

--Oil sludge(mass fraction)/% | ≯0.8 | 0.020 | IEC 61125 Act C |

--Dielectric loss factor(90°C) | ≯0.500 | 0.004 | IEC 60247 |

Gassing/(mm/min) | No general requirements | No general requirements | IEC 60628 |

Health Safety and Environmental Characteristics(HSE) | |||

Flash point(closed)/°C | ≮135 | 147.3 | ISO 2719 |

PCA content(mass fraction)/% | ≯3 | 0.8 | BS 2000 Part 346 |

Polychlorinated biphenyl(PCB)content/(mass fraction)(mg/kg) | undetectable | undetectable | IEC 61619 |

1. Market Dynamics

Electricity, an essential energy source for societal productivity and daily existence, encounters disparities in distribution owing to geographical and resource challenges, impacting local growth. China, with its burgeoning population and fast-paced power sector expansion, still experiences electricity shortages and blackouts. Hence, ultra-long-distance power transmission becomes a strategic focus to address these imbalances and promote national grid harmonization. Transformers, ubiquitous in industrial settings, urban landscapes, and essential facilities, play a pivotal role in keeping society operational. Recognizing their significance, diligent maintenance and repairs are vital to forestall transformer malfunctions, leaks, or wear and tear, thereby preserving societal order and ensuring transformer integrity.

2. Appearance and Odor Check

Checking the Clarity: Quality transformer oil should maintain a clear and transparent appearance, free from suspended impurities or settled matter. Any sign of cloudiness, murkiness, or abnormal coloration could suggest contamination or oxidation issues.

Determining the Odor: Ideal transformer oil should be devoid of any notable odor or possess a mild kerosene aroma. However, the emergence of distinct odors such as burning, acetylene, or sourness points to a decline in oil quality. To identify these odors, gently mix the oil sample and apply gentle heat. Following this, apply a few drops of the warmed oil to clean hands and rub them together for a more accurate assessment.

Own Factory

Employees at Working

Canned Oil Products

Transportation

Enterprise Culture

At the heart of our corporate culture lies honesty, which we uphold as the fundamental pillar. We are steadfast in our conviction that sincerity in interpersonal dealings fosters enduring trust and collaboration. Our business practices emphasize crystal-clear communication, steadfast commitment fulfillment, and embodying the mantra 'words into deeds, deeds into results,' thereby collectively nurturing an ecosystem of ethical commerce.

Brand Story

As HaiKun Petrochemical Technology Co., Ltd. looks ahead, it remains faithful to the guiding principle of "Innovation as the Engine of Growth, Quality as the Navigator of Tomorrow," steadfastly advancing in the petrochemical landscape with ambitions to lead the world in petrochemical product supply. The company vows to maintain its investment momentum in research and development, staying abreast of the global petrochemical technology frontier. This includes fostering continuous technological breakthroughs and product enhancements, supported by the establishment of a robust R&D ecosystem that attracts top talent. HaiKun Petrochemical will strengthen ties with renowned international research institutions and enterprises, collaborating on the exploration of novel petrochemical technologies, processes, and applications. Additionally, the company actively aligns with the national green and low-carbon development agenda, pioneering the development of environmentally conscious, efficient, and sustainable petrochemical products, thereby contributing significantly to the global energy transformation.