What happens when transformer oil is heated?

Transformer oil is a critical component within power transformers, playing pivotal roles in insulation and heat dissipation. When this oil is heated, a series of physical and chemical changes occur, which have far - reaching implications for the performance and reliability of the transformer.

Physical Changes

Viscosity Alteration

One of the immediate physical changes in transformer oil upon heating is a reduction in viscosity. Viscosity is a measure of a fluid's resistance to flow. At normal operating temperatures, transformer oil has a certain viscosity that allows it to circulate smoothly within the transformer, facilitating efficient heat transfer. As the temperature rises, the kinetic energy of the oil molecules increases. This increased energy causes the molecules to move more freely, reducing the intermolecular forces that hold them together. Consequently, the oil becomes less viscous and flows more easily. For instance, in a large power transformer operating under heavy load, where the internal temperature can soar, the transformer oil's reduced viscosity enables it to reach all the hotspots within the transformer quickly, enhancing the cooling process. However, if the temperature drops significantly after heating, the oil's viscosity will increase again, which could potentially impede its flow if the viscosity becomes too high.

Volume Expansion

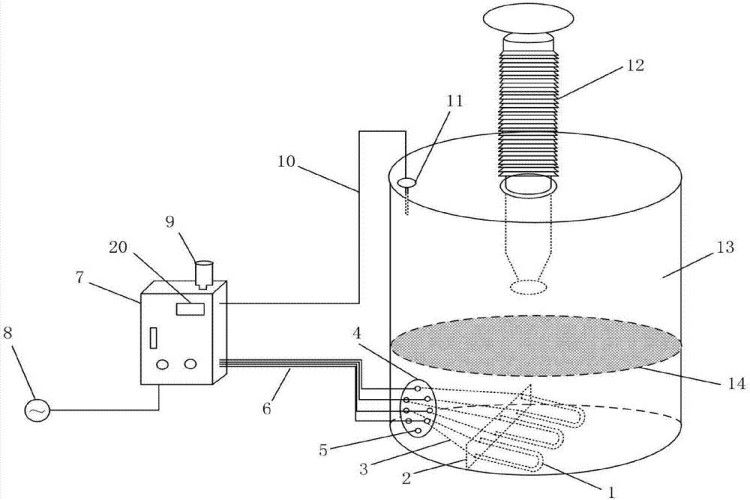

Heating also leads to the expansion of transformer oil. Similar to most substances, transformer oil expands as its temperature rises. This is because the increased kinetic energy of the molecules causes them to move further apart, resulting in an increase in volume. The coefficient of thermal expansion of transformer oil is relatively small but still significant enough to be considered in transformer design. In sealed transformers, this volume expansion can cause an increase in internal pressure. If the pressure exceeds the design limits of the transformer's enclosure, it can lead to issues such as oil leaks or damage to the seals. To mitigate this problem, transformers are often equipped with devices like conservators. A conservator is a small tank connected to the main transformer tank. It provides a space for the oil to expand and contract as the temperature changes, maintaining a relatively stable pressure within the transformer.

Chemical Changes

Oxidation Acceleration

When transformer oil is heated, especially in the presence of oxygen, the rate of oxidation accelerates. Oxidation is a chemical reaction where the hydrocarbons in the oil react with oxygen. This reaction can lead to the formation of various oxidation products, including organic acids, peroxides, and sludge. Organic acids can lower the pH of the oil, making it more acidic. This acidity can corrode the metal components within the transformer, such as the windings and the tank. Peroxides are unstable compounds that can further react with the oil, causing more degradation. The formation of sludge is particularly troublesome as it can clog the cooling channels and filters within the transformer. Clogged channels reduce the oil's ability to circulate, which in turn impairs the cooling efficiency. To slow down oxidation, antioxidants are often added to transformer oil during the manufacturing process. These antioxidants work by reacting with the free radicals generated during oxidation, thereby preventing the chain reaction that leads to extensive oil degradation.

Decomposition

At high temperatures, transformer oil can decompose. The complex hydrocarbon molecules in the oil break down into simpler compounds, such as gases (e.g., methane, ethane, and hydrogen) and volatile organic compounds. This decomposition is an endothermic reaction, meaning it absorbs heat. The decomposition process can be accelerated by factors like the presence of metal catalysts (from the transformer's components), high - voltage electrical stress, and prolonged exposure to high temperatures. The formation of gases within the oil can be a serious issue. Gas bubbles can disrupt the electrical insulation properties of the oil. In high - voltage applications, these bubbles can act as sites for electrical breakdown, leading to arcing and potential damage to the transformer. Additionally, the release of volatile compounds can contribute to the formation of flammable mixtures in the vicinity of the transformer, increasing the fire risk.

Impact on Transformer Performance

Insulation Degradation

The physical and chemical changes in transformer oil due to heating have a direct impact on its insulation properties. The reduction in dielectric strength, caused by oxidation products and gas bubbles from decomposition, means that the oil is less effective at insulating the electrical components within the transformer. As a result, the risk of electrical arcing and short - circuits increases. In extreme cases, a complete breakdown of the insulation can occur, leading to a major electrical fault. This not only causes the transformer to fail but can also disrupt the power supply to a large area, resulting in significant economic losses.

Cooling Inefficiency

Heating - induced changes in the oil can also lead to cooling inefficiency. The formation of sludge and the clogging of cooling channels, as a result of oxidation and decomposition, impede the oil's flow. With reduced flow, the oil cannot effectively transfer heat away from the hotspots in the transformer. This causes the temperature within the transformer to rise further, creating a vicious cycle. Higher temperatures accelerate the oil's degradation, further reducing its cooling capabilities. If the cooling inefficiency is not addressed, the transformer may overheat, which can cause permanent damage to the windings and other critical components.

In conclusion, heating transformer oil triggers a series of physical and chemical changes that can severely compromise the performance and reliability of transformers. Understanding these changes is crucial for the proper operation, maintenance, and design of transformers to ensure the safe and efficient delivery of electrical power.